Understanding the importance of testing & commissioning for your UPS system

Thorough and comprehensive UPS testing & commissioning is critical for a number of reasons, namely: validating its operational performance, but also protecting your hardware from faulty and potentially dangerous irregularities.

When investing large sums of money in your business, you need to ensure that the equipment you will be relying on – can indeed be relied upon.

Failing to do this can be costly for your business as you can easily miss potential flaws and weaknesses that can otherwise be unearthed through careful and controlled testing. Read on and we’ll share a comprehensive guide to ensuring your UPS installation was successful.

Preparing for UPS system testing & commissioning

Before you start testing & commissioning your UPS system, there are a few boxes you’ll need to tick off:

Necessary tools and equipment

The first step is to make sure that you have all of the necessary tools and equipment to carry out thorough testing & commissioning. These include (but are not limited to):

- Regular hand tools

- Torque wrench

- Thermometer

- Hydrometer

- Oscilloscope

- Load bank

- Current tester

- Digital Volt-ohm metre

- Ductor

- Protective relay set

- Manufacturer’s instruction manual

Don’t forget your personal protective equipment!

Safety precautions

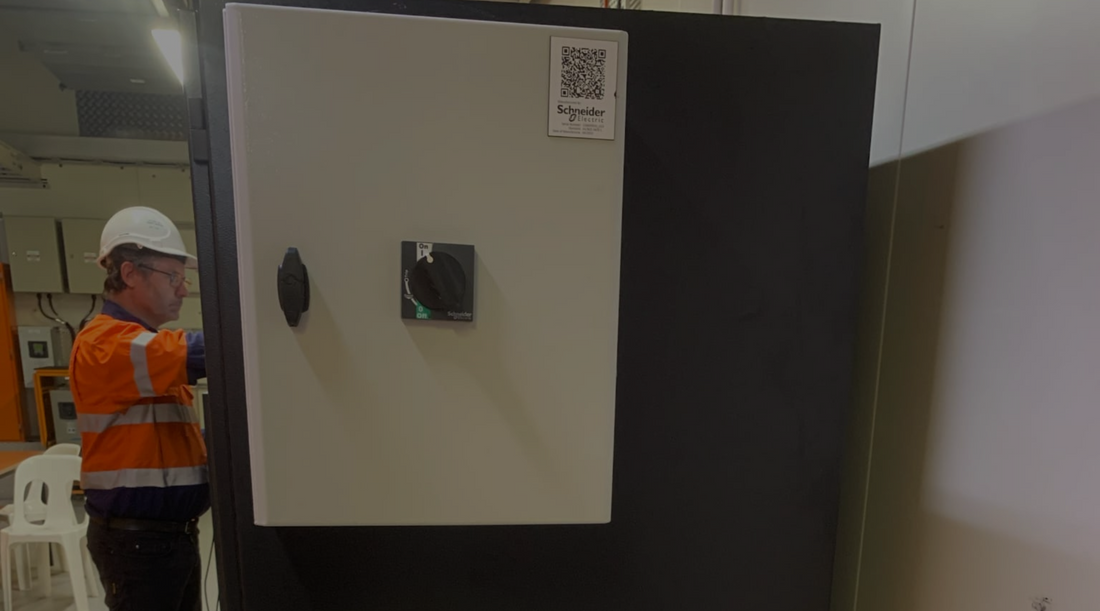

Once you have all of the necessary tools and equipment, next you must take all of the appropriate safety precautions such as site safety inductions and carrying out initial checks (i.e., looking for damp and/or damage).

The best way to avoid any complication is to hire the professionals for installation & maintenance services. That way, they can ensure that everything is installed properly – followed by comprehensive testing & commissioning before signing off and giving you the green light.

Testing your UPS system

Initial inspection and checks

- Begin by visually inspecting all equipment for signs of potential damage or foreign materials.

- Next, check the room’s ventilation, cleanliness, and whether or not the proper signage / other safety factors are established.

- Check all power connections are tight.

- Check all of the control wiring terminations and plugs for proper seating and tightness.

- Check the DC bus for potential short circuit

- Check the input and Bypass power for proper phase rotation and voltages

- Check all of the lamp test functions.

- Verify all alarms.

- Energise UPS module / ensure DC, walk-up and AC phase are on.

- Check DC link holding voltages.

- Check for proper sync.

- Perform full-load, step-load, and battery discharge tests.

Functional testing

Functional testing for UPS systems involves testing the system and all its intended functions. This includes:

- Steady-state load test

- Harmonic analysis

- Filter integrity

- Transient load testing

- Module fault test

- Battery run-down test

Performance testing

As the name suggests, performance testing is all about making sure that your UPS system will perform well under an actual load in a variety of different conditions. This includes:

- Load-bank testing

- Rundown testing

- Burn-in testing

- Capacity testing

Acceptance testing

Acceptance testing (aka Factory Acceptance Testing / Factory Witness Testing) simulates real-life load situations in order to ensure that the UPS system and its components work properly and meet the agreed upon specifications. Acceptance testing also includes a variety of site inspections and simulations (e.g., static-state tests / failure simulations), as well as multiple conformity checks.

Commissioning your UPS system

Configuration and calibration

While commissioning your UPS you will need to ensure that your batteries are properly configured and calibrated. Performing battery calibration will essentially ‘force’ the UPS’ battery to turn on, run out, and charge back up again – thus teaching your UPS system that the true runtime is.

Load bank testing

Load bank testing is designed to measure and validate the operational performance (and battery health) of your UPS system. This allows you to accurately assess the condition of your battery system while keeping an eye out for any failures and irregularities in individual blocks.

Maintenance of your UPS system

Maintaining your UPS system is an essentiality. Here’s a look at some of the best practices:

Best practices for maintenance

- Safety first, always

- Schedule regular maintenance with the professionals

- Maintain detailed records

- Carry out regular UPS inspections

- Recognise the fact that your UPS system’s components will eventually fail

- Assign daily and weekly tasks to trained staff

Common maintenance issues and solutions

Below are some common maintenance issues and solutions; be sure to add them to your maintenance service schedule.

- Faulty batteries: which can be avoided through regular testing and timely replacement of batteries.

- Old capacitors: which should be swapped out every 5 to 7-years.

FAQs on UPS system testing & commissioning

What is the difference between functional testing and performance testing for UPS systems?

It ultimately comes down to purpose:

- Performance testing checks how the UPS system performs under varying conditions.

- Functional testing simply checks that it actually works, full stop.

Can I perform acceptance testing on my UPS system myself, or do I need to hire a professional?

Acceptance testing can be performed by the end user, however, it’s always worth hiring a professional for a second set of eyes.

How often should I have my UPS system load bank tested?

At the very least you should have your UPS system’s load bank tested once a year.