Contact the team

Ensure Your Mission-Critical

Operations Stay Up 24/7

Experience our top-tier power and cooling solutions designed specifically for ANZ & the Pacific Region.

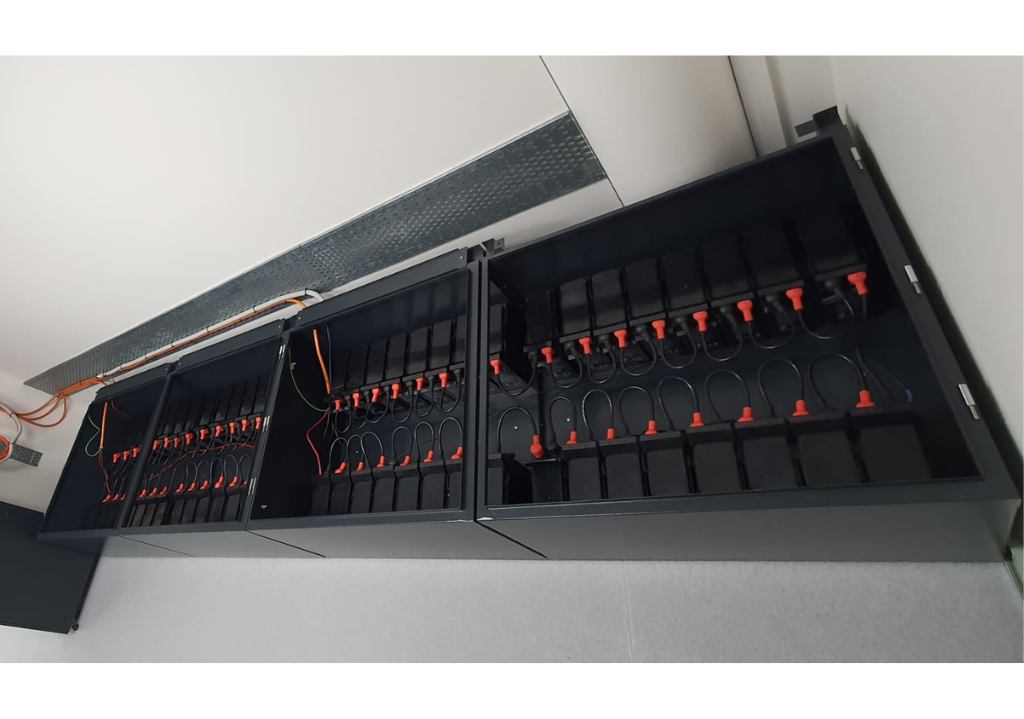

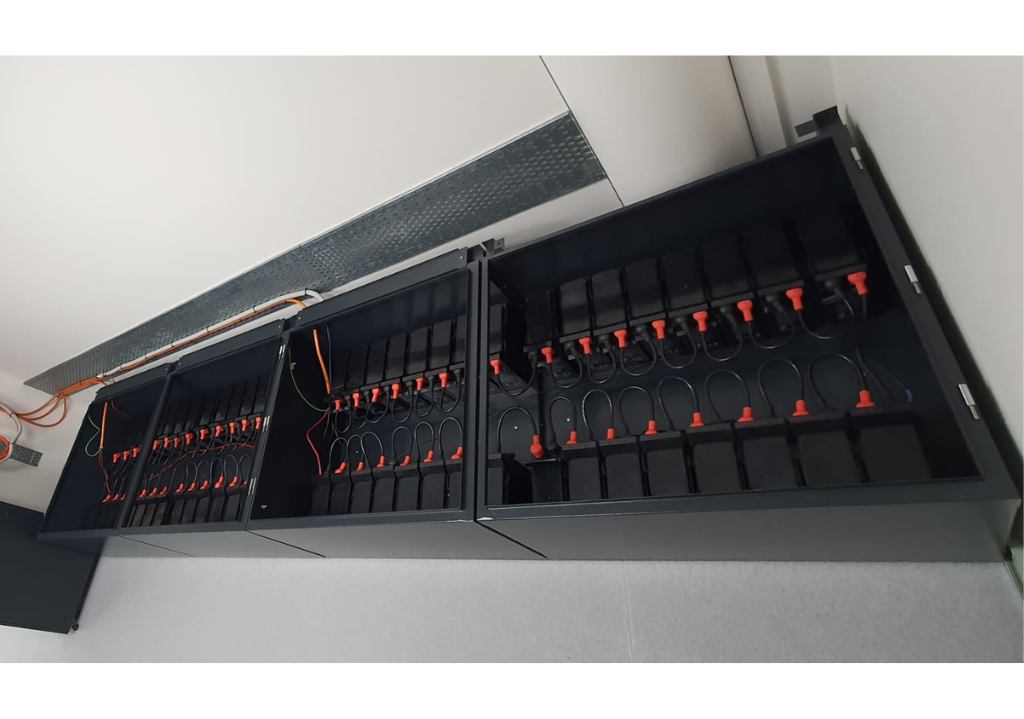

Battery Monitoring Systems

Contact the team

Experience our top-tier power and cooling solutions designed specifically for ANZ & the Pacific Region.